- Published on

Designing a New High-Voltage Connector for the Chevy Volt Replacement Battery

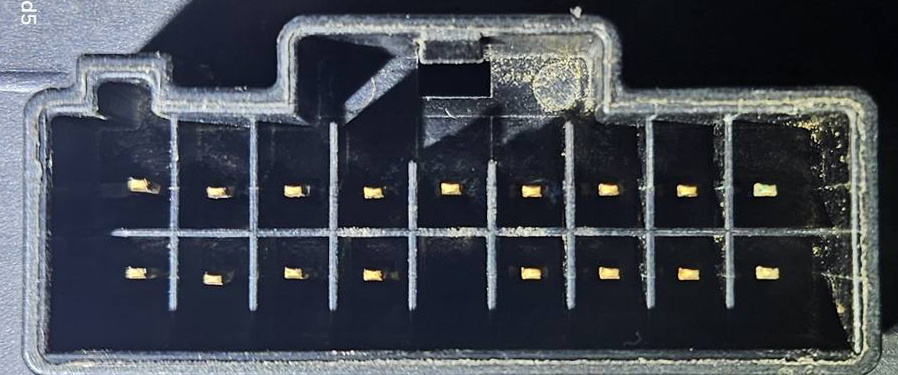

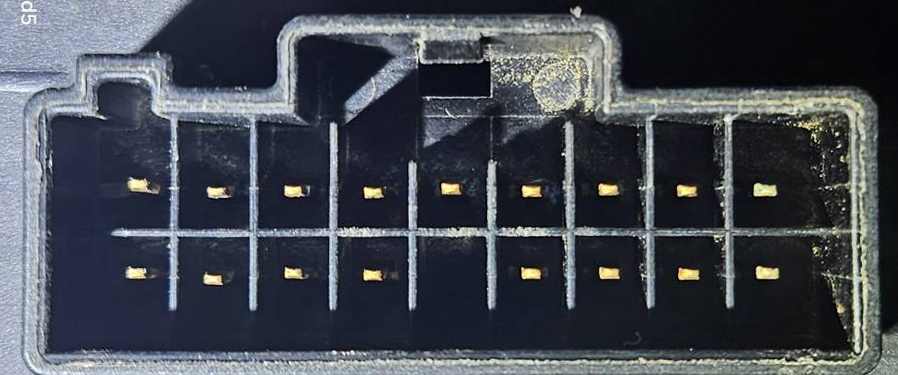

One of the most challenging — and exciting — parts of building our new replacement battery pack for the Chevy Volt is creating the high-voltage connector system that bridges our battery to the Volt’s existing wiring and control modules. While it might seem like “just a plug,” this component plays a critical role in performance, safety, and long-term reliability.

Why We Need a New Connector

The original Chevy Volt battery connector is purpose-built for GM’s pack layout and module design. Since our pack uses a different cell configuration — 18650 cells arranged in modules — we can’t simply re-use the OEM connector without major compromises.

We need:

- Electrical compatibility with the Volt’s Battery Energy Control Module (BECM) and High Voltage Powertrain Control Module 2 (HPCM2).

- Mechanical security so the connector locks firmly but can be serviced if necessary.

- Weatherproofing to protect against corrosion and moisture.

- High current handling to safely manage the pack’s peak discharge rates.

Our Design Process

We started with the OEM connector footprint to ensure plug-and-play compatibility with the Volt’s harness. From there, we modeled a new housing in CAD, focusing on:

- Pin layout & load capacity – ensuring each contact is rated above the Volt’s maximum current draw.

- Sealing surfaces – integrating silicone O-rings and gaskets to keep out dust and moisture.

- Strain relief – so cable movement doesn’t stress solder joints or crimp points.

- Heat management – using copper alloy contacts with gold plating for low resistance and better thermal performance.

Materials & Prototyping

We’re using:

- Glass-filled nylon for the connector housing (high strength, heat-resistant).

- Marine-grade copper contacts plated in gold for conductivity and corrosion resistance.

- EPDM rubber gaskets for weather sealing.

The prototype housings are being 3D printed for test fits, while contact pins are CNC-machined. This allows us to refine tolerances before moving to injection molding.

Testing & Validation

Before we roll out the production connector, we’ll test for:

- Vibration resistance – simulating road conditions.

- Thermal cycling – ensuring no cracks or loosening over time.

- Electrical load – confirming it can handle sustained and peak amperage safely.

- Ingress protection – targeting IP67 water/dust resistance.

Why This Matters

This connector is the bridge between our modernized battery pack and the Volt’s proven powertrain. By designing it to meet — or exceed — OEM specs, we’re ensuring that owners can confidently upgrade to our replacement pack without sacrificing performance, safety, or serviceability.

As we finalize the design, we’ll share more photos and possibly a behind-the-scenes look at the CAD models and test rigs.