A New Layer—Not a Replacement (Yet)

Our upcoming piggyback infotainment kit, built around the Khadas VIM3 Pro, is designed to co‑exist with the Chevrolet Volt’s factory systems—not rip them out. From day one, the stock infotainment, safety systems, and displays remain fully intact. Our platform rides alongside them, carefully cooperating with factory logic while opening the door to modern features, deep visibility, and long‑term upgrades.

This approach is intentional. The Volt is already a beautifully engineered car with an exceptional safety record. Our goal is to coax out its full potential, not override it.

1. Modern Infotainment, Fully Customizable

The piggyback system allows a next‑generation infotainment experience while preserving the original GM interface.

Key capabilities include:

- Co‑existence with the stock infotainment system

- Use of the factory display, with optional support for upgraded displays

- Support for Apple CarPlay, Android Auto, and virtually any Android‑based app

- Optional THX‑grade audio output, with add‑on amplifiers and speakers

- A fully customizable interface tailored to how you use your Volt

We’re also developing Volt‑specific custom apps, including tools to:

- Clear diagnostic codes

- Recover or “unbrick” a vehicle when possible

- Enable remote assistance, allowing a qualified professional to securely help diagnose issues from afar

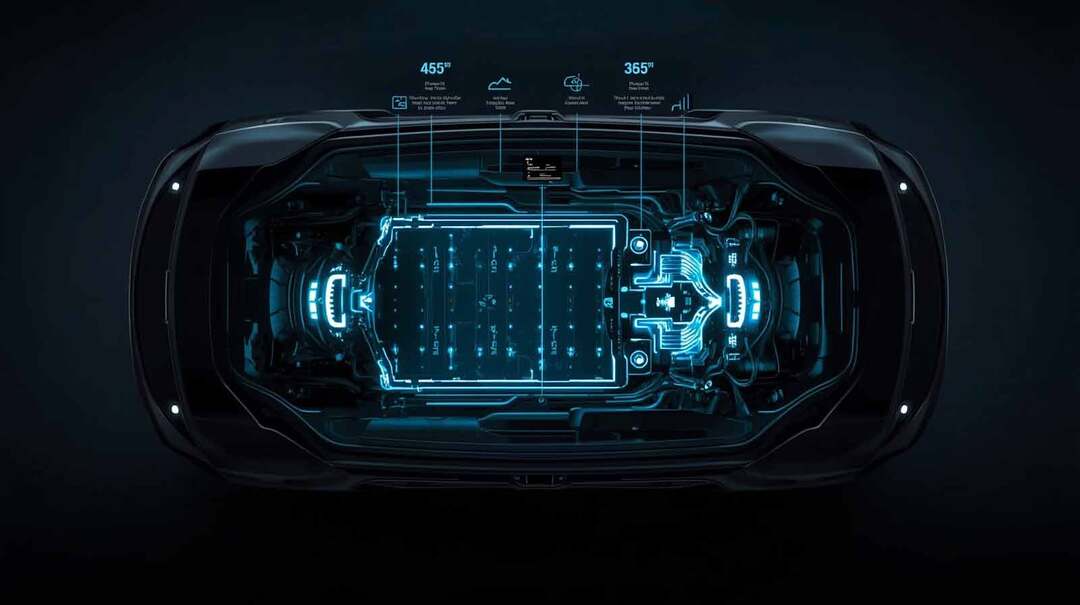

2. Real‑Time Insight the Dealer Tools Don’t Show

Dealer scan tools often summarize or obscure what’s really happening under the hood. Our system provides high‑resolution, real‑time visibility into areas that matter most to Volt owners:

- Propulsion limits

- Battery constraints and derating reasons

- Arbitration logic between vehicle systems

- Thermal and power management behavior

This data isn’t just for curiosity—it’s foundational for diagnostics, longevity, and smarter energy use.

3. Safe Feature Enablement & Experimentation

The platform is built to support controlled experimentation, always in cooperation with factory safety systems.

Potential capabilities include:

- New or refined drive modes

- Tuned regenerative braking feel

- Improved energy management strategies

- Optimized thermal behavior

Safety is non‑negotiable. Our software will not allow actions that could damage the vehicle or endanger occupants. Every feature is designed to respect the Volt’s existing protections.

4. A Gateway to Future Capabilities

The piggyback architecture also serves as an interface layer for what comes next:

- Advanced driver‑assist experimentation

- Future autonomy features as the technology matures

- New hardware integrations we haven’t even imagined yet

By adding intelligence around the vehicle instead of replacing it, the Volt becomes upgradeable in ways most cars never will be.

Designed for Longevity, Not Hacks

It’s taken years to reach a balance where systems are modifiable and safe at the same time. We deliberately avoided releasing dangerous tools that could be abused or harm the Volt’s reputation.

Instead of seizing control, our platform works with the car—extending its value, usefulness, and lifespan.

With our upcoming replacement and extended‑range battery packs, the Volt evolves into:

- An ideal city commuter

- A confident long‑distance road‑trip vehicle

- A car free from range anxiety

Future paths may include DC fast charging, or potentially skipping straight to solid‑state batteries. If owners are investing in a premium pack, it should be truly next‑generation—not a compromise.

Data Today, Reliability Tomorrow

While the infotainment system co‑exists with the stock setup, it also performs a critical role: data collection.

The VIM3 Pro continuously monitors vehicle and battery metrics to help us:

- Determine battery health

- Track internal resistance and cell balance trends

- Detect early warning signs before they trigger a check‑engine light

This data feeds into a centralized system where AI analyzes trends across the fleet, similar to what GM once did before 3G connectivity was retired—only now, owners stay informed.

If our AI detects a developing issue anywhere in your vehicle systems, you’re notified early, while it’s still a manageable situation.

Connectivity Options

Data is transmitted securely via:

- Wi‑Fi (lower cost)

- 4G LTE (faster, always connected)

Owners can choose the option that best fits their needs.

Beyond the Volt: A Universal CAN‑Bus Vision

While the Volt is our starting point, it’s not the end.

We plan to offer similar piggyback systems for any CAN‑bus‑based vehicle, enabling:

- Custom infotainment platforms

- CAN message collection and decoding

- Long‑term support for vehicles at risk of being orphaned

Our priority is EVs, where battery availability can determine whether a car lives or dies. Our mission is simple: no vehicle should be abandoned because replacement or upgraded batteries don’t exist.

With AI accelerating CAN‑bus analysis, we can move faster than ever—freeing engineers to focus on the next most critical platforms.

The Bigger Picture

This is more than an infotainment upgrade.

It’s a foundation for:

- Safer modifications

- Smarter diagnostics

- Longer vehicle lifespans

- A future where EVs improve with age instead of becoming e‑waste

The Volt just happens to be the perfect place to start.