- Published on

Laser Cutting & 3D Printing the Chevy Volt Battery Case

Laser Cutting & 3D Printing of the Battery Case Is Under Way!

Big news — the 3D printing of our custom Chevy Volt replacement battery case is in full swing, and if all goes according to plan, it may be shipping to us as early as Wednesday! This is a major step toward completing our prototype pack for Volt and Cadillac ELR owners.

Why This Case Matters

Our new battery pack design uses 18650 cells in nine modules, arranged differently from the OEM pack. That means we needed a completely new case to:

- Fit the updated cell layout

- Protect the cells from vibration and impact

- Maintain proper cooling and ventilation

- Integrate new connector designs

Rather than repurposing an OEM case, we opted to build one from the ground up — giving us total control over form, fit, and function.

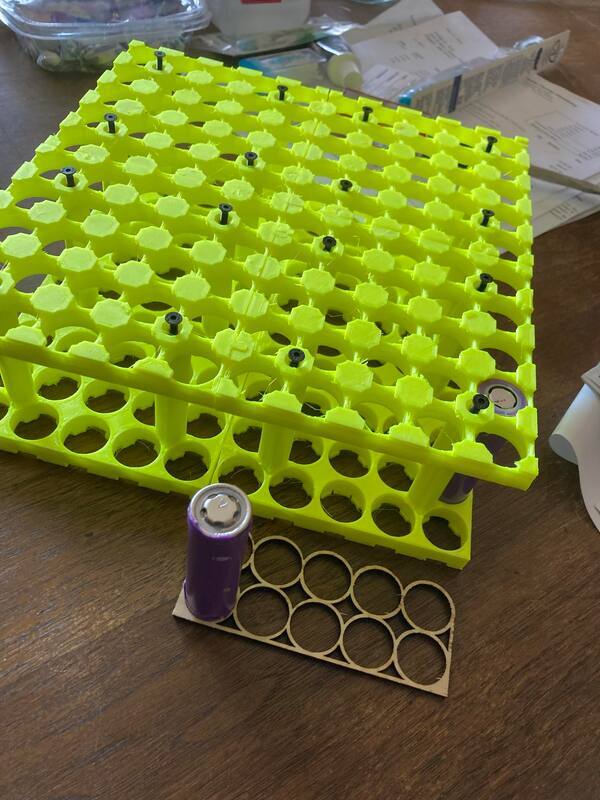

Combining Laser Cutting & 3D Printing

The case isn’t just 3D printed. We’re combining laser-cut metal components for strength and 3D printed structural pieces for precision fit and complex geometry.

- Laser Cutting:

- The base plate, mounting points, and reinforcement ribs are laser-cut from aluminum for light weight and durability. Laser cutting gives us:

- Tight tolerances

- Clean edges without post-processing

- Consistent repeatability for future production runs

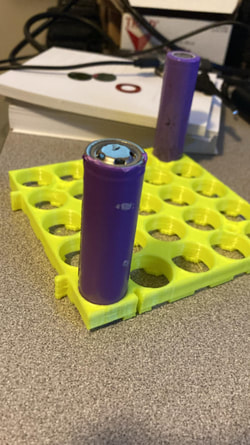

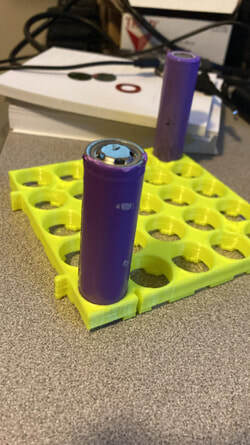

- 3D Printing:

- The cell holders, wiring channels, and case panels are being printed in glass-filled nylon — a material that’s lightweight, strong, and heat-resistant. 3D printing lets us:

- Rapidly prototype changes

- Create custom cable routing features

- Build complex shapes that can’t be machined easily

From CAD to Reality

The case was modeled entirely in CAD, then split into sections for printing and cutting. The design process involved:

- Thermal simulations to ensure proper cooling

- Finite element analysis to predict strength under load

- Alignment features so assembly is foolproof

After printing, the panels will be cleaned, heat-treated for added strength, and bonded to the laser-cut framework.

What’s Next

Once the case arrives this week, we’ll:

- Test-fit all cell modules

- Install the new high-voltage connector we just designed

- Begin final assembly of the prototype pack

This hybrid fabrication approach — combining laser-cut precision with 3D printing flexibility — ensures our battery case will be both strong enough for daily driving and custom-fit for our upgraded design.